- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 6 Chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

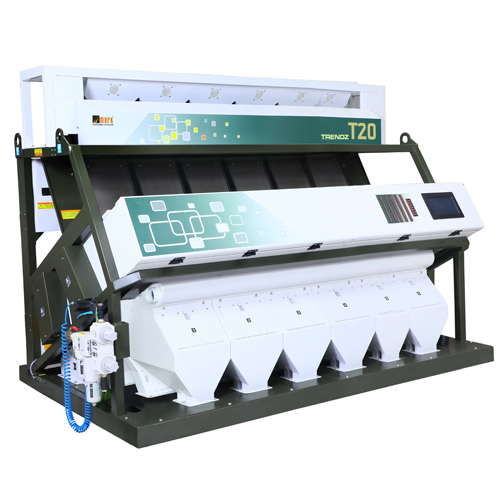

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Garlic Color Sorting Machine

- Coffee Seed Color Sorter

- Dry Grapes Color Sorter Machine

- Millet Color Sorter

- Belt Drive Color Sorter Machine

- Elachi Color Sorting Machine

- Kismis Colour Sorting Machine

- Chilli Colour Sorter Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Moong Dal Colour Sorter

- Toor Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

Double Boiled Rice Colour Sorting Machine

2500000 INR/Unit

Product Details:

- Usage Commercial

- Air Pressure 0.6-0.8 MPa

- Type Double Boiled Rice Colour Sorting Machine

- Air Compressor Required, 7.5 HP or above

- Accuracy 99 %

- Dimension (L*W*H) 2200 x 1550 x 1800 mm

- Output 2-5 tons/hour

- Click to View more

X

Double Boiled Rice Colour Sorting Machine Price And Quantity

- 1 Unit

- 2500000 INR/Unit

Double Boiled Rice Colour Sorting Machine Product Specifications

- 64-320

- 900-1200 kg

- Double boiled rice colour sorting, grain industry

- 2-5 tons/hour

- 3-6 kW

- 2-5 tons/hour

- 2200 x 1550 x 1800 mm

- Required, 7.5 HP or above

- 99 %

- Commercial

- 0.6-0.8 MPa

- Double Boiled Rice Colour Sorting Machine

Double Boiled Rice Colour Sorting Machine Trade Information

- 60 Unit Per Month

- 15 Days

Product Description

Product Features

Mark Color Sorter is designed to provide a superior performance and reliability, allowing you to avoid annoying maintenance which would effect your production. Mark Color sorter is a complete system that incorporates advanced engineering concepts.

Specification

| Frequency | 50 Hz |

| Power Source | Electric |

| Brand | Mark |

| Voltage | 230 V |

| Automation Grade | Automatic |

| Model Name/Number | T20 Series |

Tri Chromatic Camera Scanner

- High Speed data acquisition and digital imag

- Processing Technology Using FPG

- Resolution - 5400 X 3 pixels with RGB Trichromatic Camera Technol

- Highly Specialized lens for sorting purpose

- Front and back evenly aligned cameras with digital alignment technology

10 Inch Color HMI

- Low Energy consumption led lighting

- Improves fine RGB Illumination in background

- Enhancing defects recognition systems by varying different backgrounds for different types of grains

Specifications:-

| Chute Option Available | 12 Chute | 10 Chute | 8 Chute | 7 Chute | 6 Chute | 5 Chute | 4 Chute | 3 Chute | 2 Chute | 1 Chute |

| Chute Distribution (P+S+F) | 7+3+2 or 7+2+2+1 | 6+2+2 or 6+2+1+1 | 5+2+1 or 4+2+1+1) | 4+2+1 or 4+2+(40+21) | 4+1+1 or 4+2+(40+21) | 3+1+1 or 3+1+(40+21) | 2+1+1 or 2+1+(40+21) | 2+1 or 2+(40+21) | 1+1 or 1+(40+21) | - |

| Output (TPH) for Rice/Dal | 7 to 9 | 6 to 8 | 5 to 7 | 4 to 6 | 3.5 to 4.5 | 3 to 5 | 2 to 4 | 1.5 to 2.5 | 1 to 2 | 0.75 to 1.5 |

| No.of.camera (F&R) | 12+12 | 10+10 | 8+8 | 7+7 | 6+6 | 5+5 | 4+4 | 3+3 | 2+2 | 1+1 |

| Air@7.5kg/Cm2 | 230 CFM | 180 CFM | 160 CFM | 140 CFM | 115 CFM | 96 CFM | 72 CFM | 54 CFM | 44 CFM | 28 CFM |

| Compressor Requirement | 50 HP Screw | 40 HP Screw | 35 HP Screw | 35 HP Screw | 30 HP Screw | 25 HP Screw | 20 HP Screw | 15 HP Screw | 10 HP Screw | 10 HP Screw |

| Dimension (LXWXH) feet | 16x4.88x5.97 | 13.83x4.88x5.97 | 10.87x4.88x5.97 | 9.73x4.88x5.97 | 8.59x4.88x5.97 | 7.46x4.88x5.97 | 6.33x4.88x5.97 | 5.19x4.88x5.97 | 4.1x4.88x5.97 | 2.92x4.88x5.97 |

| Cabin Dimension Feet (LXWXH) | 20x10x8 | 18x10x8 | 16x10x8 | 14x10x8 | 13x10x8 | 12x10x8 | 10x10x8 | 9x10x8 | 8x10x8 | 7x10x8 |

Advanced CCD Camera-Based Sorting

Equipped with state-of-the-art CCD cameras, this rice colour sorter ensures precise detection and accurate separation of discoloured grains or impurities. The advanced imaging, combined with 64 to 320 channels and LED-based illumination, guarantees consistent and reliable results for all types of double boiled and steamed rice.

User-Friendly and Robust Design

The sorter features a 10-inch color touch screen for straightforward operation and monitoring. Its stainless steel frame ensures longevity, while the low-noise design keeps the working environment pleasant. The machine also employs a vibratory feeding system for smooth and even material distribution during sorting.

Industrial Efficiency and Safety

With a sorting capacity of 2-5 tons per hour and compatibility with commercial air compressors (7.5 HP or above), this machine is ideal for exporters, suppliers, and manufacturers in the rice and grain industry. Low power consumption (3-6 kW) and precise control mechanisms make it both efficient and reliable.

FAQ's of Double Boiled Rice Colour Sorting Machine:

Q: How does the Double Boiled Rice Colour Sorting Machine achieve such high sorting accuracy?

A: The machine utilizes advanced CCD camera technology and a multi-channel sorting system (64-320 channels) to accurately detect defects and colour variations in rice grains, resulting in a sorting accuracy greater than 99% with a reject rate below 0.5%.Q: What types of rice and grains are suitable for processing with this machine?

A: This machine is optimized for double boiled rice, steam rice, and boiled rice. It can also effectively sort similar grains used in the grain industry, making it versatile for various commercial applications.Q: When should an air compressor be used with this sorting machine?

A: An air compressor with at least 7.5 HP and operating pressure of 0.6-0.8 MPa is required during machine operation, as it powers the ejectors that remove defective grains from the sorting channels.Q: Where can this colour sorter be installed and used?

A: The machine is designed for commercial-scale use in rice mills, grain processing plants, and export facilities. Its robust construction allows installation in industries across India and other regions requiring strict sorting standards.Q: What is the process involved in sorting rice with this machine?

A: Rice is fed into the machine via a vibratory feeding system, illuminated by LED lights, and scanned by CCD cameras. The system automatically sorts and separates grains based on pre-set colour parameters, ensuring only the best quality output.Q: How does the touch screen interface benefit operators during daily use?

A: The 10-inch color touch screen enables operators to easily set parameters, monitor machine performance, and execute automatic control functions, streamlining the sorting process and reducing manual intervention.Q: What are the main advantages of using this rice colour sorter in a commercial setting?

A: Key benefits include exceptional sorting accuracy, low reject rates, high output (2-5 tons/hour), low operational noise, energy-efficient lighting, and durable stainless steel construction, all of which contribute to enhanced productivity and consistent product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email