- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 6 Chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

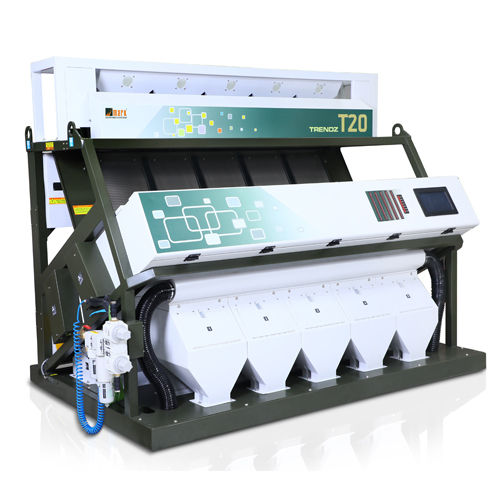

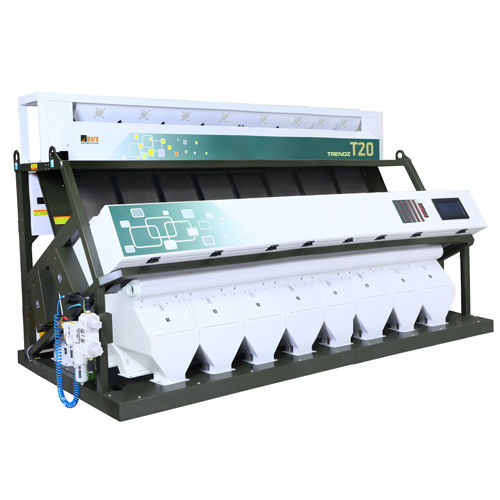

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Garlic Color Sorting Machine

- Coffee Seed Color Sorter

- Dry Grapes Color Sorter Machine

- Millet Color Sorter

- Belt Drive Color Sorter Machine

- Elachi Color Sorting Machine

- Kismis Colour Sorting Machine

- Chilli Colour Sorter Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Moong Dal Colour Sorter

- Toor Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

White Rice Color Sorter

1700000 INR/Unit

Product Details:

- Channels 64 to 256 (customizable)

- Accuracy 99 %

- Usage Commercial

- Air Compressor Required, 0.6-0.8 Mpa

- Dimension (L*W*H) 1750 x 1630 x 1900 mm

- Air Pressure 0.6-0.8 MPa

- Weight Approx. 600 kg

- Click to View more

X

White Rice Color Sorter Price And Quantity

- 1 Unit

- 1700000 INR/Unit

White Rice Color Sorter Product Specifications

- Commercial

- 1-3 Tons/Hr

- 99 %

- Approx. 600 kg

- 64 to 256 (customizable)

- 2.2 kW

- 0.6-0.8 MPa

- Up to 3 Tons per Hour

- 1750 x 1630 x 1900 mm

- White Rice Color Sorter

- Required, 0.6-0.8 Mpa

- Sorting and grading of rice based on color and quality

White Rice Color Sorter Trade Information

- 60 Unit Per Month

- 15 Days

Product Description

To meet the requirements of our customers, we are able to offer top class White Rice Color Sorter for our valued clients. Our expert engineers manufacture these machines by making use of modern machines in our well-equipped infrastructure facility. The premium grade components and materials required to manufacture and design these machines are sourced from the trusted vendors of the market. The White Rice Color Sorter is very durable and efficient, therefore demanded by our patrons across the market.

Specification

| Head Pulses Recovery | 80-90% |

| Material of Construction | MS |

| Electricity Connection | Single Phase |

| Type of Pulses | All Pulses |

| Operation Mode | Automatic |

| Capacity | 1.5 to 3 TPH |

| Country of Origin | Made in India |

Features:

- High performance

- Operational fluency

- Sturdy construction

- Longer service life

Cutting-Edge CCD Sensor-Based Sorting

Equipped with a 5400-pixel CCD camera and LED lighting, the White Rice Color Sorter excels in detecting even minor defects or color variations. Its advanced sensors ensure high precision in separating discolored, damaged, or foreign rice grains, enhancing overall rice quality. The technology significantly reduces human involvement, providing rapid and consistent sorting results.

Highly Efficient and Customizable Output

Designed to accommodate varying commercial needs, the rice color sorter can process 1 to 3 tons per hour, making it suitable for medium to large-scale operations. The number of channels, ranging from 64 to 256, can be tailored according to specific sorting requirements, ensuring optimal performance and flexibility for exporters, manufacturers, and suppliers.

User-Friendly Operation and Robust Construction

Featuring a 10-inch PLC touch screen, the system allows for easy configuration and monitoring. The stainless steel chute ensures durability and hygiene, while the overall structure guarantees longevity and resistance to industrial wear. Noise reduction features maintain a quieter workplace, with operation noise controlled below 75 dB.

FAQ's of White Rice Color Sorter:

Q: How does the CCD sensor-based technology work in the White Rice Color Sorter?

A: The CCD sensor-based system scans each rice grain using a high-resolution 5400-pixel camera, capturing color and quality details. The collected data is processed in real-time, and grains that differ from set parameters are accurately separated using high-speed solenoid valve ejectors.Q: What types of rice can be sorted with this machine?

A: This color sorter is designed for white rice but can be adapted to sort various grades and types of rice based on color and quality differences, providing versatility for different commercial applications.Q: When should I use a rice color sorter in my processing operation?

A: A rice color sorter is typically used after milling, prior to packaging, to ensure only high-quality, defect-free rice proceeds to market. This step is crucial for exporters and suppliers aiming for premium output standards.Q: Where is the White Rice Color Sorter typically installed?

A: The sorter is ideal for commercial rice processing facilities, including exporter, manufacturer, and supplier units in India or similar markets. It requires a well-ventilated area with sufficient space for its operational footprint and air compressor requirements.Q: What is the process for operating the White Rice Color Sorter?

A: Operators load the rice into the machine, configure sorting parameters using the 10-inch touch screen PLC, and start the process. The system uses LED lights and CCD cameras for inspection; rejected grains are separated by solenoid valves, and quality rice continues for packaging.Q: How is the air compressor used in this sorting system?

A: The air compressor provides the necessary 0.6-0.8 MPa pressure to drive the solenoid valves, which precisely eject faulty or discolored grains without damaging the rice, ensuring efficient and accurate sorting.Q: What are the key benefits of using this color sorter?

A: Users benefit from enhanced sorting accuracy (up to 99%), reduced waste with a rejection ratio below 0.2%, higher throughput (up to 3 tons per hour), improved product consistency, and an overall increase in commercial market value of sorted rice.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email