- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 6 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

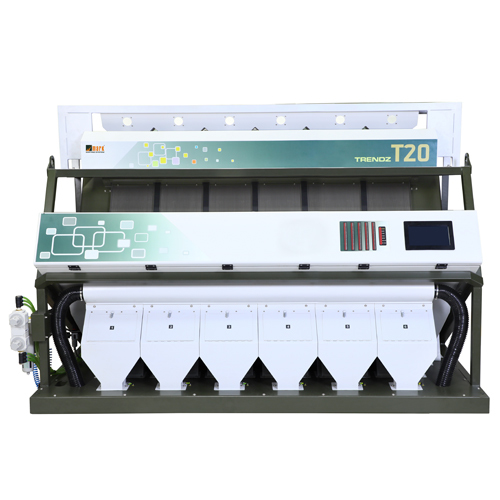

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Dry Grapes Color Sorter Machine

- Coffee Seed Color Sorter

- Belt Drive Color Sorter Machine

- Elachi Color Sorting Machine

- Millet Color Sorter

- Garlic Color Sorting Machine

- Kismis Colour Sorting Machine

- Chilli Colour Sorter Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Toor Dal Colour Sorter

- Moong Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

Peanut Colour Sorting Machine

2225000 INR/Piece

Product Details:

- Type Peanut Colour Sorting Machine

- Application Peanut, Groundnut Sorting

- Weight 600 kg

- Power 2.5 kW

- Air Compressor Required, not included

- Output 3T/H

- Air Pressure 0.60.8 MPa

- Click to View more

X

Peanut Colour Sorting Machine Price And Quantity

- 1 Piece

- 2225000 INR/Piece

Peanut Colour Sorting Machine Product Specifications

- 99.9% mm/m

- 3T/H

- 32 channels

- Commercial

- Required, not included

- 2.5 kW

- 600 kg

- Peanut Colour Sorting Machine

- 0.60.8 MPa

- 3 T/hr

- 1500 1620 1852 mm

- Peanut, Groundnut Sorting

Peanut Colour Sorting Machine Trade Information

- 5 Piece Per Month

- 45 Days

Product Description

In order to maintain the highest standards of quality, we manufacture and supply supreme quality Peanut Color Sorting Machine. The offered machine is highly demanded in food processing industries due to its smooth operation and high production capacity. The optimal components and upgraded technology used in the manufacturing of this machine are of premium grade. Also, we can supply this Peanut Color Sorting Machine to clients at a reasonable price in varied technical specifications based on their application requirements.

Tri Chromatic Camera Scanner

- Acquire data and create digital images at high-speed

- Using FPGA technology as a processing technology

- The camera has a resolution of 5400 x 3 pixels with RGB trichromatic imaging technology

- High-quality lens for the purpose of sorting

- A front and back camera that are evenly aligned

10'' Inch Color HMI

- Energy-efficient LED lighting

- Fine RGB illumination in the background is improved

- By varying the background for different types of grains, defects recognition systems can be improved

Specification

| Head Pulses Recovery | 80-90% |

| Material of Construction | MS |

| Electricity Connection | Single Phase |

| Type of Pulses | All Pulses |

| Operation Mode | Automatic |

| Capacity | 3 to 4.5 TPH |

| Country of Origin | Made in India |

High-Precision Colour Sorting

Utilizing cutting-edge CCD high-resolution cameras and a full-color RGB sorting system, this machine accurately detects and separates defective peanuts. The result is a consistently high-quality output, with an impressive 99.9% sorting accuracy, ensuring that only optimal peanuts proceed for packaging and sale.

Durable and Efficient Design

Built with stainless steel housing and highly durable ejector valves (6-10 billion cycles), this sorter offers exceptional stability and longevity. The low-noise operation ( 75 dB) and long lamp life (up to 80,000 hours) make it perfectly suited for continuous commercial use.

User-Friendly Operation

Featuring an intuitive touchscreen interface, operators can easily set and monitor sorting parameters. The simple yet robust controls reduce downtime and ensure seamless integration into existing processing lines, making it more accessible for users of varying experience levels.

FAQ's of Peanut Colour Sorting Machine:

Q: How does the Peanut Colour Sorting Machine enhance sorting efficiency?

A: The machine utilizes CCD high-resolution cameras and full-color RGB technology to accurately identify and separate defective peanuts. Its rapid 32-channel sorting and robust air ejectors facilitate efficient sorting of up to 3 tons per hour, maximizing processing output without sacrificing quality.Q: What is the process for operating the sorting machine?

A: Operation is straightforward via its touchscreen control system. Fill the 45-liter hopper with peanuts, select the sorting parameters on the touchscreen, and ensure an air compressor is connected (0.6-0.8 MPa). The machine then automatically identifies and removes defects, delivering sorted output with minimal manual intervention.Q: When should maintenance be performed on the machine?

A: Routine maintenance should follow usage intensity, but critical components like the ejector valves and lamps are designed for longevity, with lifespans of 6-10 billion cycles and up to 80,000 hours respectively. Regular cleaning and periodic technical checks are recommended to maintain peak performance.Q: Where is this machine most suitable for use?

A: This commercial-grade peanut colour sorter is ideal for processing plants, export hubs, supplier depots, and large-scale manufacturing facilities. Its robust design allows operation in diverse Indian climatic conditions, from -20C up to +50C.Q: What are the primary benefits of using this sorting machine?

A: Key benefits include ultra-high sorting accuracy (99.9%), rapid processing at 3T/hr, reduced manual labour, and minimized contamination or defects in sorted peanuts. Its durable components and intuitive controls further contribute to operational cost savings.Q: Is an air compressor included with the peanut sorting machine?

A: No, the air compressor is required for optimal performance but is not included with the machine. It should provide air pressure within the range of 0.6-0.8 MPa to ensure reliable operation of the sorting ejectors.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free