- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 6 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

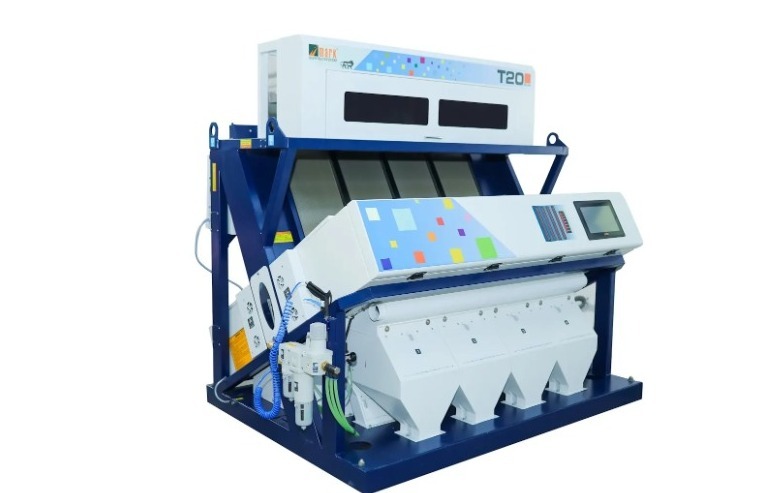

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Dry Grapes Color Sorter Machine

- Coffee Seed Color Sorter

- Belt Drive Color Sorter Machine

- Elachi Color Sorting Machine

- Millet Color Sorter

- Garlic Color Sorting Machine

- Kismis Colour Sorting Machine

- Chilli Colour Sorter Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Toor Dal Colour Sorter

- Moong Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

T20 Square 7 chute Color Sorter

2700000 INR/Unit

Product Details:

- Power 7.5 kW

- Output High Throughput, Continuous Operation

- Usage Industrial Sorting

- Dimension (L*W*H) 3705mm 1795mm 2102mm

- Weight 2200 kg

- Air Pressure 0.60.8 MPa

- Capacity 79 tons/hour (depending on material)

- Click to View more

X

T20 Square 7 chute Color Sorter Price And Quantity

- 2700000 INR/Unit

- 1 Unit

T20 Square 7 chute Color Sorter Product Specifications

- 10 HP or higher, Oil-free Recommended

- Sorting rice, grains, pulses, seeds, plastic, minerals

- 99.99%

- T20 Square 7 Chute Color Sorter

- 7

- 0.60.8 MPa

- 79 tons/hour (depending on material)

- Industrial Sorting

- High Throughput, Continuous Operation

- 3705mm 1795mm 2102mm

- 2200 kg

- 7.5 kW

T20 Square 7 chute Color Sorter Trade Information

- Coimbatore

- 10 Unit Per Month

- 7 Days

- All India

Product Description

Specifications:-ïï

| Chute Option Available | 12 Chuteï | 10 Chute | 8 Chute | 7 Chute | 6 Chute | 5 Chute | 4 Chute | 3 Chute | 2 Chute | 1 Chute |

| Chute Distribution (P+S+F) | ï ï7+3+2ï ï ï ï ïorï ï ï 7+2+2+1 | ï ï ï6+2+2ï ï ï ï ï ï ï orï ï ï ï ï 6+2+1+1 | ï ï ï ï5+2+1ï ï ï ï ï ï ï ïorï ï ï ï ï4+2+1+1 | ï ï 4+2+1ï ï ï ï ï ï ïorï ï ï ï ï ï ï4+2+(40+21) | 4+1+1ï ï ï ï ï ï orï ï ï ï ï ï ï 4+2+(40+21) | 3+1+1ï ï ï ï ï ï orï ï ï ï ï ï ï ï3+1+(40+21) | 2+1+1ï ï ï ï ï ï orï ï ï ï ï ï ï 2+1+(40+21) | ï ï2+1ï ï ï ï ï ï ï ï ï orï ï ï ï ï ï ï ï 2+(40+21) | ï ï 1+1ï ï ï ï ï ï ï ï ï ïorï ï ï ï ï ï ï 1+(40+21) | - |

| Output (TPH) for Rice/Dal | 7 to 9 | 6 to 8 | 5 to 7 | 4 to 6 | 3.5 to 4.5 | 3 to 5 | 2 to 4 | 1.5 to 2.5 | 1 to 2 | 0.75 to 1.5 |

| No.of.camera (F&R) | 12+12 | 10+10 | 8+8 | 7+7 | 6+6 | 5+5 | 4+4 | 3+3 | 2+2 | 1+1 |

| Air@7.5kg/Cm2 | 230 CFM | 180 CFM | 160 CFM | 140 CFM | 115 CFM | 96 CFM | 72 CFM | 54 CFM | 44 CFM | 28 CFM |

| Compressor Requirement | 50 HP Screw | 40 HP Screw | 35 HP Screw | 35 HP Screw | 30 HP Screw | 25 HP Screw | 20 HP Screw | 15 HP Screw | 10 HP Screw | 10 HP Screw |

| Dimension (LXWXH) feet | 16x4.88x5.97 | 13.83x4.88x5.97 | 10.87x4.88x5.97 | 9.73x4.88x5.97 | 8.59x4.88x5.97 | 7.46x4.88x5.97 | 6.33x4.88x5.97 | 5.19x4.88x5.97 | 4.1x4.88x5.97 | 2.92x4.88x5.97 |

| Cabin Dimension Feet (LXWXH) | 20x10x8 | 18x10x8 | 16x10x8 | 14x10x8 | 13x10x8 | 12x10x8 | 10x10x8 | 9x10x8 | 8x10x8 | 7x10x8 |

Advanced Sorting Technology

The T20 Square 7 Chute Color Sorter integrates both CCD and NIR sensor technologies, ensuring precise color detection and impurity rejection for a wide variety of materials. Its 2048-pixel full-color CMOS sensors and double-sided camera scanning provide highly accurate sorting results for industrial applications.

High Capacity and Efficiency

Handling between 7 to 9 tons per hour depending on material type, this machine is engineered for continuous, high throughput operations. Its 7-channel design, durability, and fast ejector response make it ideal for exporters and large-scale manufacturers seeking reliable, uninterrupted performance.

User-Friendly and Robust Design

The 15-inch touch screen interface provides intuitive control, while the entire systems designwith a 50,000-hour LED service life and a low noise level below 75 dBensures operator comfort and minimal maintenance. Its heavy-duty construction supports industrial environments and varied working conditions in India.

FAQs of T20 Square 7 chute Color Sorter:

Q: How does the T20 Square 7 Chute Color Sorter use its sensors to detect and sort materials?

A: This sorter leverages advanced CCD and NIR sensors, along with double-sided 2048-pixel high-resolution CMOS cameras, to precisely identify and separate unwanted materials based on minute color and property differences across rice, grains, pulses, seeds, plastics, and small stones.Q: What materials can be sorted with this color sorter?

A: The T20 Square 7 Chute Color Sorter is versatile and compatible with rice, grains, pulses, seeds, plastic, and even small stones, making it suitable for a wide range of industrial sorting tasks.Q: When is maintenance required for the machines light source and ejector valves?

A: The LED light source has a service life of 50,000 hours, while the ejector valves are rated for up to 5 billion uses, minimizing routine maintenance interruptions and ensuring prolonged, reliable operation in industrial settings.Q: Where is the T20 Square 7 Chute Color Sorter commonly used?

A: As an industrial-grade sorter, it is widely employed in food processing plants, seed cleaning facilities, grain exporters, plastics recyclers, and mineral sorting operationsparticularly in India, where it is manufactured, supplied, and exported.Q: What is the sorting process like for this machine?

A: Materials are loaded into the sorter and pass through the 7 chutes, where high-speed cameras and sensors analyze every particle. When impurities or discrepancies are detected, rapid air ejectors remove them, ensuring high purity of the output product.Q: How does the touch screen interface benefit operators?

A: The 15-inch industrial-grade touch screen provides an intuitive, user-friendly interface, allowing operators to monitor and adjust sorting settings with ease, ensuring seamless operation even in high-demand environments.Q: What are the main benefits of using the T20 Square 7 Chute Color Sorter?

A: Key benefits include unmatched sorting accuracy (99.99%), high throughput (79 tons/hour), minimal reject rate (0.2%), long component life, low maintenance, and compatibility with a wide variety of industrial materials, all contributing to higher product quality and operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free