- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 6 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

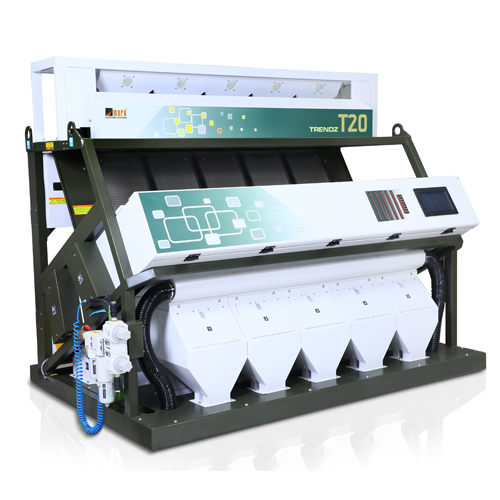

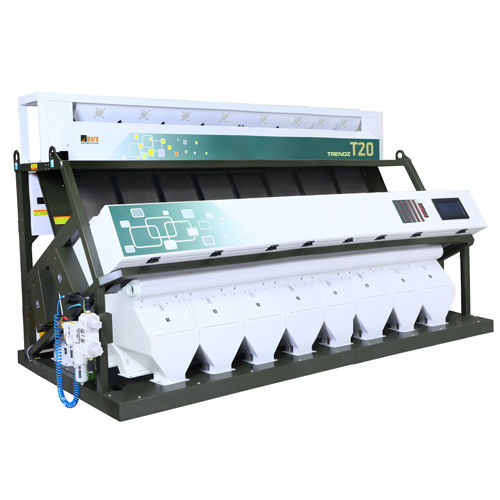

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Dry Grapes Color Sorter Machine

- Belt Drive Color Sorter Machine

- Garlic Color Sorting Machine

- Coffee Seed Color Sorter

- Millet Color Sorter

- Elachi Color Sorting Machine

- Chilli Colour Sorter Machine

- Kismis Colour Sorting Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Toor Dal Colour Sorter

- Moong Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

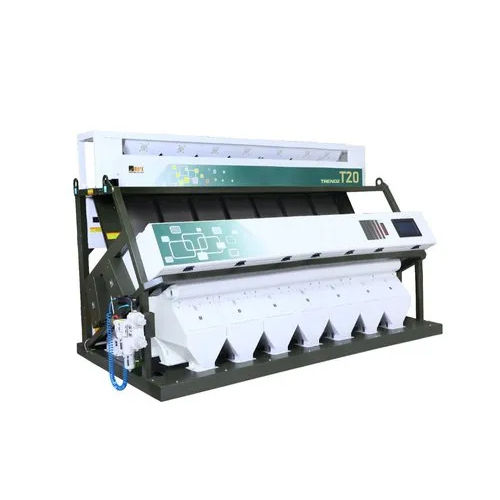

Half Boiled Rice Colour Sorter

2500000 INR/Piece

Product Details:

- Usage Commercial

- Air Pressure 0.6-0.8 Mpa

- Capacity 3 to 4.5 TPH

- Accuracy 99 %

- Application Sorting Half Boiled Rice

- Dimension (L*W*H) 1545*1560*1955 mm

- Output 3000-4500 Kg/hr

- Click to View more

X

Half Boiled Rice Colour Sorter Price And Quantity

- 1 Piece

- 2500000 INR/Piece

Half Boiled Rice Colour Sorter Product Specifications

- 99 %

- 7

- 800 Kg

- 3 to 4.5 TPH

- 0.6-0.8 Mpa

- 4.5 Watt (w)

- 3000-4500 Kg/hr

- Commercial

- 1545*1560*1955 mm

- Half Boiled Rice Colour Sorter

- 7.5 hp

- Sorting Half Boiled Rice

Half Boiled Rice Colour Sorter Trade Information

- 60 Piece Per Month

- 15 Days

Product Description

The Half Boiled Rice Colour Sorter has been designed to provide superior performance and reliability, allowing you to avoid costly maintenance that would slow down the production process. An advanced engineering approach is used in the design of the sorting machine.

Tri Chromatic Camera Scanner:

- High-speed data collection and digital imaging

- FPGA Processing Technology

- RGB Trichromatic Technology with a resolution of 5400 x 3 pixels

- Sorting lens with high specialization

- With digital alignment technology, the front and back cameras are evenly aligned

10'' Inch Color HMI

- LED lighting with low energy consumption

- Background RGB illumination is improved

- Developed a system to recognize defects by varying the background color for various grain types

Exceptional Sorting Accuracy

Achieve superior results with our colour sorter's advanced CCD camera sensor technology, ensuring 99.99% sorting accuracy for half boiled rice. The precision-driven system confidently distinguishes defects and discolorations, providing consistently uniform output while keeping reject rates below 0.2%. Drive business success with reliable, high-quality rice processing every cycle.

User-Friendly Controls & Maintenance

Operate with ease using the touch screen PLC interface for intuitive control and quick adjustments. The self-cleaning feature and accessible design streamline maintenance-minimizing downtime and ensuring long-lasting performance. Included spare parts, such as sorter trays and air filters, simplify routine servicing, letting you focus on productivity.

Engineered for Efficiency & Reliability

Built with SS304 stainless steel, this colour sorter withstands demanding commercial use while maintaining a low noise level of under 70 dB. The vibratory feeding system ensures even rice distribution, while efficient LED lighting and advanced image processing deliver cost-effective sorting. The system operates reliably across a wide temperature range, supporting continuous, high-volume rice processing.

FAQ's of Half Boiled Rice Colour Sorter:

Q: How does the CCD camera sensor technology enhance the sorting process?

A: The CCD camera sensor in the Half Boiled Rice Colour Sorter captures high-resolution images of each rice kernel, enabling accurate detection of colour differences and imperfections. This ensures that only defect-free rice passes through, raising the consistency and quality of your output.Q: What is the recommended operating temperature range for this rice sorter?

A: This sorter operates optimally between -20C and 50C, providing flexibility and reliable performance across varying environmental conditions often encountered in commercial facilities.Q: When should routine maintenance be performed, and how is cleaning managed?

A: Routine maintenance is simplified with the self-cleaning mechanism. Regularly inspect spare parts such as air filters, nozzles, and the sorter tray, typically as recommended by the manufacturer or when prompted by system alerts. The self-cleaning function minimizes manual intervention, keeping the machine running efficiently.Q: Where can the Half Boiled Rice Colour Sorter be installed for best results?

A: It's designed for commercial rice processing units, export facilities, and large-scale supplier plants. Ensure installation in a clean, spacious area with a stable power supply (220V/50Hz) and adequate air compression (0.6-0.8 Mpa) for optimum sorting performance.Q: What is the sorting process used by this machine?

A: Rice is fed into the machine via a vibratory feeder, passes under LED-lit CCD cameras for defect detection, and is then sorted based on set parameters. Advanced image processing and air jets swiftly separate discoloured or defective grains with a reject rate below 0.2%, maintaining a high accuracy of 99.99%.Q: How can using this colour sorter benefit my business?

A: By ensuring precise rice sorting and reducing rejection rates, your business delivers higher-quality products, increases efficiency, and meets export standards. The machine's capacity (up to 4.5 TPH) boosts throughput, while its low noise and power consumption (4.5W) reduce operational costs.Q: What spare parts are included with the rice colour sorter?

A: The package includes essential spare parts for smooth operation: sorter tray, air filters, and nozzle. These components assist with maintenance and help ensure continuous and reliable sorting performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email