- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 6 Chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

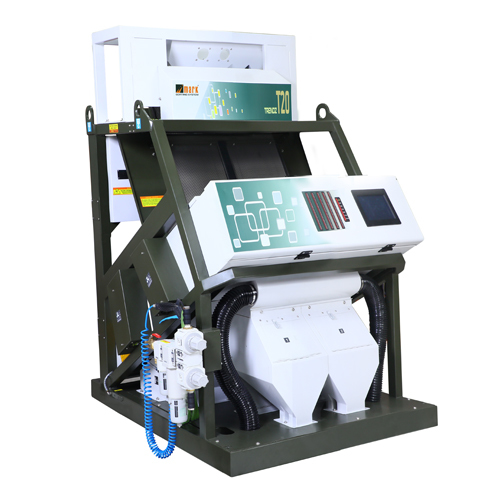

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Garlic Color Sorting Machine

- Coffee Seed Color Sorter

- Dry Grapes Color Sorter Machine

- Millet Color Sorter

- Belt Drive Color Sorter Machine

- Elachi Color Sorting Machine

- Kismis Colour Sorting Machine

- Chilli Colour Sorter Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Moong Dal Colour Sorter

- Toor Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

Chana Dal Color Sorting Machine

1300000 INR/Unit

Product Details:

- Output Adjustable based on sorting grade

- Capacity 1 to 5 Tons/hour (varies by model)

- Type Chana Dal Color Sorting Machine

- Channels 64, 128 (model dependent)

- Application Chana Dal, Pulses, Grain Sorting

- Dimension (L*W*H) 2200 x 1620 x 1850 mm

- Accuracy 99.9%

- Click to View more

X

Chana Dal Color Sorting Machine Price And Quantity

- 1 Unit

- 1300000 INR/Unit

Chana Dal Color Sorting Machine Product Specifications

- 7.5 HP (Recommended)

- Commercial

- 99.9%

- Chana Dal, Pulses, Grain Sorting

- 64, 128 (model dependent)

- 700 kg (approx.)

- 2200 x 1620 x 1850 mm

- Adjustable based on sorting grade

- Chana Dal Color Sorting Machine

- 1 to 5 Tons/hour (varies by model)

- 2.5 kW

- 0.6-0.8 MPa

Chana Dal Color Sorting Machine Trade Information

- 60 Unit Per Month

- 15 Days

Product Description

Our clients can purchase from us Chana Dal Color Sorting Machine of high quality. We have a team of highly skilled professionals who use only the highest quality components and materials. The performance and durability make this sorter preferred by our customers. Our huge infrastructure facility features advanced tools and machines that allow us to manufacture such machines for sorting purposes. It is quality checked before delivery to ensure its proper performance. It operates for a long time period without requiring maintenance, thus improving production.

Tri Chromatic Camera Scanner

- Collects data and creates digital images at high speed

- Processing Technology utilizing FPGA

- Resolution of 5400 X 3 pixels along with RGB Trichromatic Camera Technology

- Highly Specialized lens to sort chana dal color sorting machine

- An even alignment of the front and back cameras is achieved by using digital alignment technology

10'' Inch Color HMI

- Led lighting that consumes less energy

- Enhances RGB illumination in the background

- Variations in background color is possible to suit different types of grains can improve defect recognition

Specification

| Head Pulses Recovery | 80-90% |

| Power Consumption | 3 KVA |

| Material of Construction | MS |

| Electricity Connection | Single Phase |

| Type of Pulses | All Pulses |

| Operation Mode | Automatic |

| Model Name/Number | T20 Series |

| Brand | Mark |

Advanced Dual-Side Inspection Technology

The Chana Dal Color Sorting Machine combines state-of-the-art CCD camera and NIR sensors, enabling double-sided inspection of each kernel. This ensures high precision in sorting, detecting even subtle differences in color and quality, reducing contamination in the final product.

Efficient and Intuitive Operation

Equipped with a 10-inch color touchscreen interface, operators can quickly select sorting grades, adjust output, and monitor performance. The vibratory feeding system with smart control delivers consistent material flow, maximizing throughput and minimizing downtime for commercial operations.

Robust Construction and Capacity

Weighing approximately 700 kg and designed with durable materials, this color sorter can manage 1 to 5 tons per hour, depending on the model. With 64 or 128 channels and a powerful air ejector system, it ensures minimal reject ratios while processing high volumes efficiently.

FAQ's of Chana Dal Color Sorting Machine:

Q: How does the Chana Dal Color Sorting Machine achieve high sorting accuracy?

A: The machine uses advanced CCD camera and NIR (Near Infrared) technologies with double-sided inspection, allowing precise detection of defects and color inconsistencies. Its high-speed solenoid ejectors ensure only unwanted grains are separated, achieving up to 99.9% accuracy.Q: What types of products can be processed with this sorting machine?

A: This sorter is designed for chana dal but is also suitable for sorting various pulses and grains. Its adaptable settings and superior detection capabilities make it a versatile solution for commercial sorting applications.Q: When should I use this machine in my processing workflow?

A: The ideal stage to use the color sorter is after initial cleaning and grading, before final packaging. It ensures contaminants and discolored grains are efficiently removed, resulting in a high-quality end product.Q: Where can this sorting machine be installed?

A: This color sorter is suited for commercial food processing plants, dal mills, and pulse/grain exporting facilities. Its manageable dimensions (2200 x 1620 x 1850 mm) make it easy to integrate into existing production lines.Q: What is the process for sorting with this machine?

A: Product is fed via the vibratory feeding system, passing under powerful LED illumination. The double-sided cameras and NIR sensors scan each particle, and undesired items are ejected using fast-response solenoid valves, maintaining a minimum reject ratio of 1:6.Q: How is the machine's output adjusted according to sorting grade?

A: The 10-inch touchscreen interface allows operators to adjust sorting parameters, output capacities, and sorting grades in real time, catering to specific quality requirements and optimizing efficiency based on the type of material processed.Q: What are the main benefits of using this color sorter for chana dal processing?

A: Key benefits include significant improvement in product quality, high processing precision, reduced labor costs, minimal reject ratios, and enhanced throughput. The machine's intuitive controls and reliable performance promote higher profitability for businesses in the pulse and grain sector.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free