- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- 1 Chute Commandor Color sorter

- Commandor Model 6 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 12 Chute Color Sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

- Commandor Model 10 Chute Color Sorter

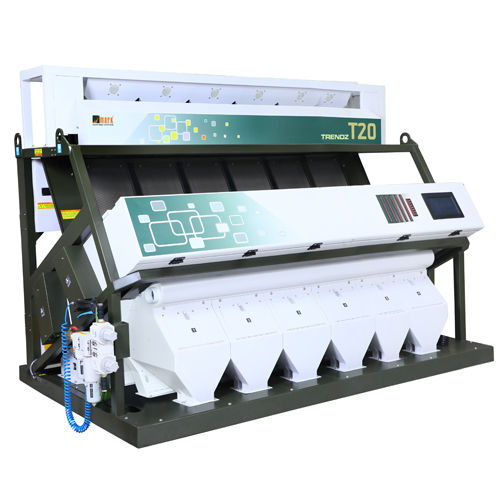

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Basmati Rice Color Sorter Machine

- Steam Rice Color Sorter Machinery

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Millet Color Sorter

- Coffee Seed Color Sorter

- Dry Grapes Color Sorter Machine

- Elachi Color Sorting Machine

- Belt Drive Color Sorter Machine

- Garlic Color Sorting Machine

- Kismis Colour Sorting Machine

- Chilli Colour Sorter Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Moong Dal Colour Sorter

- Toor Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorter Machine

- Wheat Color Sorting Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

Masoor Dal Color Sorter

2400000 INR/Unit

Product Details:

- Channels 64

- Weight Approx. 700 kg

- Usage Commercial

- Dimension (L*W*H) 1450*1270*1800 mm

- Capacity 500-2000 kg/hour

- Application Dal Sorting, Pulses Processing

- Type Masoor Dal Color Sorter

- Click to View more

X

Masoor Dal Color Sorter Price And Quantity

- 2400000 INR/Unit

- 1 , , Unit

Masoor Dal Color Sorter Product Specifications

- 1450*1270*1800 mm

- Commercial

- Approx. 700 kg

- 64

- 0.6 - 0.8 MPa

- 99 %

- Masoor Dal Sorting

- Dal Sorting, Pulses Processing

- 500-2000 kg/hour

- Required (External)

- 2.2 kW

- Masoor Dal Color Sorter

Masoor Dal Color Sorter Trade Information

- 60 , , Unit Per Month

- 15 Days

Product Description

Mark Color Sorter is designed to provide a superior performance and reliability, allowing you to avoid annoying maintenance which would effect your production. Mark Color sorter is a complete system that incorporates advanced engineering concepts.

Tri Chromatic Camera Scanner

- High Speed data acquisition and digital image

- Processing Technology Using FPGA

- Resolution - 5400 X 3 pixels with RGB Trichromatic Camera Technology

- Highly Specialized lens for sorting purpose

- Front and back evenly aligned cameras with digital alignment technology

10 Inch Color HMI

- Low Energy consumption led lighting

- Improves fine RGB Illumination in background

- Enhancing defects recognition systems by varying different backgrounds for different types of grains

Specifications:-

| Chute Option Available | 12 Chute | 10 Chute | 8 Chute | 7 Chute | 6 Chute | 5 Chute | 4 Chute | 3 Chute | 2 Chute | 1 Chute |

| Chute Distribution (P+S+F) | 7+3+2 or 7+2+2+1 | 6+2+2 or 6+2+1+1 | 5+2+1 or 4+2+1+1) | 4+2+1 or 4+2+(40+21) | 4+1+1 or 4+2+(40+21) | 3+1+1 or 3+1+(40+21) | 2+1+1 or 2+1+(40+21) | 2+1 or 2+(40+21) | 1+1 or 1+(40+21) | - |

| Output (TPH) for Rice/Dal | 7 to 9 | 6 to 8 | 5 to 7 | 4 to 6 | 3.5 to 4.5 | 3 to 5 | 2 to 4 | 1.5 to 2.5 | 1 to 2 | 0.75 to 1.5 |

| No.of.camera (F&R) | 12+12 | 10+10 | 8+8 | 7+7 | 6+6 | 5+5 | 4+4 | 3+3 | 2+2 | 1+1 |

| Air@7.5kg/Cm2 | 230 CFM | 180 CFM | 160 CFM | 140 CFM | 115 CFM | 96 CFM | 72 CFM | 54 CFM | 44 CFM | 28 CFM |

| Compressor Requirement | 50 HP Screw | 40 HP Screw | 35 HP Screw | 35 HP Screw | 30 HP Screw | 25 HP Screw | 20 HP Screw | 15 HP Screw | 10 HP Screw | 10 HP Screw |

| Dimension (LXWXH) feet | 16x4.88x5.97 | 13.83x4.88x5.97 | 10.87x4.88x5.97 | 9.73x4.88x5.97 | 8.59x4.88x5.97 | 7.46x4.88x5.97 | 6.33x4.88x5.97 | 5.19x4.88x5.97 | 4.1x4.88x5.97 | 2.92x4.88x5.97 |

| Cabin Dimension Feet (LXWXH) | 20x10x8 | 18x10x8 | 16x10x8 | 14x10x8 | 13x10x8 | 12x10x8 | 10x10x8 | 9x10x8 | 8x10x8 | 7x10x8 |

Superior Sorting Accuracy

Leveraging a high-resolution CCD camera, the Masoor Dal Color Sorter ensures sorting precision with 99% accuracy. The four chutes and 64 channels enable rapid and consistent performance, effectively distinguishing even subtle color variations in dal, thus guaranteeing premium product quality.

Advanced User Interface

A state-of-the-art touch screen display system allows operators to easily control and monitor the sorting process. The system features intuitive navigation, live data visualization, and settings customization, optimizing operational efficiency for commercial dal processors.

Efficient and Versatile Processing

With a robust design, this sorter enables output up to 2,000 kg/hour, making it suitable for a wide range of commercial applications, including dal sorting and pulses processing. Its operating range, from -10C to +40C, ensures year-round reliability across varied environments.

FAQ's of Masoor Dal Color Sorter:

Q: How does the CCD camera technology enhance the sorting process in the Masoor Dal Color Sorter?

A: The high-resolution CCD camera detects even subtle differences in color and impurities, allowing the sorter to accurately distinguish and separate defective or discolored masoor dal with minimal rejection and high sorting precision.Q: What is the capacity and suitability of the Masoor Dal Color Sorter for commercial operations?

A: With a processing capacity of 500 to 2,000 kg per hour and four chutes, this machine is ideal for commercial dal sorting and pulses processing, accommodating the demands of large-scale production environments.Q: When is it necessary to use an external air compressor with this color sorter?

A: An external air compressor is required whenever the machine is operational because it powers the ejectors that remove unwanted dal from the product stream, ensuring efficient and continuous sorting.Q: Where can this Masoor Dal Color Sorter be operated effectively?

A: Designed for commercial use, it functions reliably in a wide temperature range from -10C to +40C, making it suitable for processing plants and factories in various climatic conditions across India and other regions.Q: What are the key benefits of using this color sorter in dal and pulses processing?

A: The main benefits include superior sorting accuracy, reduced reject rates under 10%, increased product value, easy touch screen operation, and the ability to process large quantities quickly, improving overall efficiency and profitability.Q: How user-friendly is the touch screen display system during operation?

A: The touch screen interface is designed for ease of use, offering clear visual feedback, customizable settings, and straightforward controls, reducing training time and operator errors while enhancing productivity.Q: What role does air pressure play in the sorting process?

A: Air pressure (0.6-0.8 MPa) is vital for actuating the ejectors that remove defective or discolored dal. Proper air pressure ensures swift and precise separation, maintaining high throughput and sorting accuracy.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email