- Home Page

- Company Profile

-

Our Products

- Commandor Color Sorter Machine

- Commandor Model 12 Chute Color Sorter

- 1 Chute Commandor Color sorter

- Commandor Model 2 chute Color Sorter

- Commandor Model 3 Chute Color Sorter

- Commandor Model 4 Chute Color Sorter

- Commandor Model 6 Chute Color Sorter

- Commandor Model 5 Chute Color Sorter

- Commandor Model 8 Chute Color Sorter

- Commandor Model 10 Chute Color Sorter

- Commandor Model 7 Chute Color Sorter

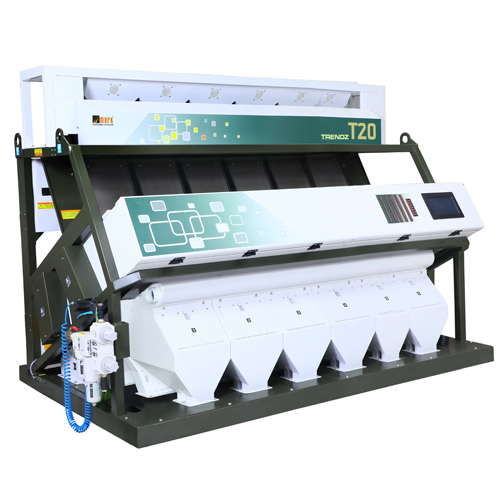

- T20 Square Color Sorter Machine

- T20 Color Sorter

- Commandor HS Color Sorter Machine

- Rotomax Belt Color Sorter Machine

- Commandor XP Color Sorter Machine

- Rice Color Sorter

- T20 Rice Colour Sorter machine

- Half Boiled Rice Colour Sorter

- Raw Rice Colour Sorter

- White Rice Color Sorter

- Double Boiled Rice Colour Sorting Machine

- Rose Rice Color Sorter

- Steam Rice Color Sorter Machinery

- Basmati Rice Color Sorter Machine

- Ponni Rice Colour Sorter Machine

- Rice Colour Sorting Machine

- Rice Blending Machine

- Rice Color Sorting Machine T20 - 12 Chute

- Rice Color Sorting Machine T20 - 7 Chute

- Rice Color Sorting Machine T20 - 6 Chute

- Rice Sorting Machine Chute T20 - 4 Chute

- Rice Sorting Machine T 20 1 Chute

- Cumin Color Sorting Machine T20 - 10 Chute

- Mark-J-Max-280 Rice Color Sorting Machine

- Smart X Rice Color Sorter

- Color Sorting Machine

- Dry Grapes Color Sorter Machine

- Belt Drive Color Sorter Machine

- Garlic Color Sorting Machine

- Coffee Seed Color Sorter

- Millet Color Sorter

- Elachi Color Sorting Machine

- Chilli Colour Sorter Machine

- Kismis Colour Sorting Machine

- Sesame And Til Seeds Color Sorting Machine T 20- 3 Chute

- CCD Color Sorting Machines

- Moong Dal Sorting Machine T20 - 12 Chute

- Color Sorting Machines

- Dal Sorter Machine - T20 6 Chute

- Dal Color Sorter

- Toor Dal Colour Sorter

- Moong Dal Colour Sorter

- Masoor Dal Color Sorter

- Pulses Colour Sorting Machine

- Urad Dal Colour Sorter

- Chana Dal Color Sorting Machine

- Toor Dal Sorting Machine T20 - 12 Chute

- Toor Dal Sorter Machine T20 1 Chute

- Pulses Color Sorting Machine T20 1 Chute

- Channa Dal Sorting Machine T20 - 10 Chute

- Grains Color Sorter

- Zorba Series Color Sorter Machine

- Cashew Nut Color Sorter

- Groundnut Color Sorter

- Wheat Color Sorter

- Wheat Color Sorting Machine

- Wheat Color Sorter Machine

- Cumin Color Sorting Machine

- Wheat Color Sorter

- Color Sorting Machine T20 - 4 Chute

- Wheat Sorter Machine

- Wheat Color Sorting Machine T20 - 12 Chute

- Wheat Color Sorting Machine T20 7 Chute

- Til Color Sorting Machine T20 - 3 Chute

- Ragi Color Sorting Machine T 20 - 3 Chute

- Wheat Color Sorting Machine T20 - 1 Chute

- Wheat Color Sorting Machine T20 - 2 Chute

- Wheat Color Sorting Machine T20 - 5 Chute

- Plastic Color Sorter Machine

- COP Sorter

- Grain Color Sorter

- Moong Dal sorting machine T20- 3 Chute

- Urad Dal Sorting Machine T20 - 2 Chute

- Cereal Color Sorter Machine

- Smart-X Color Sorter

- Grain Color Sorter For Food Industry

- Grain Color Sorters

- Grain Color Sorter Machine

- Barnyard Millet Color Sorting Machine T20-4-Chute

- Jhangora Color Sorting Machine T 20-2 Chute

- Bajra Color Sorting Machine T 20 - 5 Chute

- Ragi Color Sorting Machine T20 - 5 Chute

- Groundnut And Peanut Sorting Machine T20 - 2 Chute

- Urad Dal Sorting Machine T20 - 3 Chute

- Urad Dal Sorting Machine T20 - 4 Chute

- Urad Dal Sorting Machine T20 - 1 Chute

- Finger Millet Sorting Machine T20 - 2 Chute

- Rice Color Sorting Machine T20 -10 Chute

- Rice Sorting Machines T20 -10 Chute

- Channa Dal Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 8 Chute

- Channa Dal Sorting Machine T20 - 5 Chute

- Channa Dal Sorting Machine T20 - 4 Chute

- Channa Dal Sorting Machine T20 - 2 Chute

- Channa Dal Sorting Machine T20 - 1 Chute

- Moong Dal Sorting Machine T20- 8 Chute

- Moong Dal Sorting Machine T20 - 7 Chute

- moong Dal Sorting Machine T20 - 6 Chute

- Moong Dal Sorting Machine T20 - 5 Chute

- Moong Dal Sorting Machine T20 - 4 Chute

- Moong Dal Sorting Machine T20 - 2 Chute

- Moong Dal Sorting Machine T20-1 Chute

- Moong Dal Sorting Machine T20 - 1 Chute

- Toor Dal Sorting Machine T20-10 Chute

- Toor Dal Sorting Machine T20 - 8 Chute

- Toor Dal Sorting Machine T20-7 Chute

- Toor Dal Sorting Machine T20 - 6 Chute

- Toor Dal Sorting Machine T20-5 Chute

- Electronic Color Sorter

- Mark Trendz T20 Multi Grain Sorter

- Belt Drive Sorter Machine

- Dal Color Sorter Machine

- Dal Color Sorter

- Chana Dal Color Sorter

- Pulse Sorter Machine - T20 3 Chute

- Moong Dal Color Sorting Machine

- Dal Color Sorting Machine

- Daal Color Sorter

- Dhall Sorting Machine T20 - 1 Chute

- Pulses Sorting Machine T20- 2 Chute

- Pulses Sorting Machine T20 - 3 Chute

- Pulses Sorting Machines T20 - 4 Chute

- Pulses Sorting Machine T20 5 Chute

- Urad Dal Sorting Machine T20

- Urad Dal Sorting Machine T20 - 10 Chute

- Channa Dal Sorting Machine T20 - 6 Chute

- Urad Dal Sorting Machine T20 - 7 Chute

- Dal Color Sorting Machine T20 - 8 Chute

- Fried Gram Color Sorting Machine T20 - 3 Chute

- Channa Dal Sorting Machine T20 - 7 Chute

- Urad Dal Sorting Machine T20 - 12 Chute

- Moong Dal Sorting Machine T20 - 10 Chute

- Dall Color Sorting Machine T 20 - 2 Chute

- Fennal Seeds And Saunf Sorting Machine T 20 5 Chute

- Toor Dal Color Sorting Machine T20 - 4 Chute

- Toor Dal Sorting Machine T20 - 2 Chute

- Toor Dal Sorting Machine T20 - 3 Chute

- Pulses Sorting Machine T20 - 8 Chute

- Urad Dal Sorting Machine T0 - 5 Chute

- Multigrain Color Sorter

- Dal Mill Sorter Machine

- Dal Color Sorter Machine

- Millets Color Sorting Machine

- Millet Color Sorting Machine T20 - 2 Chute

- Sanwa Millet Color Sorting Machines T 20 - 2 Chute

- Ragi Color Sorting Machine

- Barnyard Millet Color Sorting Machine Machine T20 - 3 Chute

- Finger Millet Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 -7 Chute

- Fox Tail Millet Color Sorting Machine T20 - 3 Chute

- Kodo Millet Color Sorting Machine 3 Chute

- Kodo Millet Color Sorting Machine T20-4 Chute

- Barnyard Millet Color Sorting Machine T20 - 2 Chute

- Millets Color Sorting Machine T20 - 4 Chute

- Finger Millet Color Sorting Machine T20 - 3 Chute

- Little Finger Millet Color Sorting Machine T20 - 2 Chute

- Fox Tail Millet Color Sorting Machine T20 - 4 Chute

- Poppy And Khas Khas Color Sorting Machines

- Millets Sorting Machine T 20 - 2 Chute

- Millets Sorting Machine T20 - 8 Chute

- Millets Color Sorting Machine T20 - 5 Chute

- Fox Tail Millet Color Sorting Machine T20 - 2 Chute

- Spices Sorting Machine

- Cumin Color Sorting Machine T20 - 12 Chue

- Cumin Color Sorting Machine T20 - 6 Chute

- Sesame Seeds Color Sorting Machine T 20 - 5 Chute

- Fennel Seeds And Saunf Color Sorting Machine T20 4 -Chute

- Mustard And Raida Color Sorting Machine T20 -6 Chute

- Fennel Seeds Color Sorting Machine T20-3 Chute

- Jeera Color Sorting machine T20 - 5 Chute

- Raida Color Sorting Machine T20 - 5 Chute

- Cumin Color Sorting Machine T20- 8 Chute

- Plastic Chips Color Sorting Machine T20 - 2 Chute

- Plastic Grindings Color Sorting Machine T20 - 2 Chute

- Jeera Color Sorting Machine T20 - 6 Chute

- Fennel Seeds Color Sorting Machine T20- 10 Chute

- Sesame Seeds Color Sorting Machines T 20 - 4 Chute

- Jeera Color Sorting Machine T20 - 4 Chute

- Mustard Color Sorting Machine T20- 4 Chute

- Color Sorting Equipment

- Dal Color Sorting Machine T20 - 3 Chute

- Dal Color Sorting Machine T20 - 6 Chute

- Wheat Color Sorting Machine T20 3 Chute

- Wheat Color Sorting Machine T20 - 8 Chute

- Wheat Color Sorting Machine T20 4 Chute

- Wheat Color Sorting Machine T20 - 10 Chute

- Dal Color Sorting Machine T20 - 7 Chute

- Wheat Color Sorting Machine T20 - 6 Chute

- Dhall Color Sorting Macine T20 - 4 Chute

- Millets Sorting Machine

- Pearl Millet And Bajra Color Sorting Machine T20 - 4 Chute

- Pearl Millet Color Sorting Machine T20-5 Chute

- Pearl Millet Color Sorting Machine T20 - 3 Chute

- Cop Sorting Machine

- Pearl Millet Sorting Machine T20 - 2 Chute

- Bajra Color Sorting Machine T20 - 2 Chute

- Ragi Color Sorting Machine Machine T20 - 4 Chute

- LED Color Sorter

- Rice Color Sorting Machine

- Groundnut Color Sorting Machine

- Seeds Color Sorting Machine

- Plastic Color Sorting Machine

- Seed Sorter For Agriculture Industry

- Peanut Color Sorting Machine

- Trichromatic Color Sorter

- Cashew Color Sorter

- Rice Color Sorter Machine

- Bi and Tri Chromatic Color Sorter

- Millet Sorting Machine

- Nut Sorting Machine

- Lentils Sorting Machine

- Moisture Meter

- Garlic Sorting Machine

- Cashew Nut Sorting Machine

- Spices Color Sorter

- Magaj Sorter Machine

- Mark Commandor

- Peanut Color Sorter Machine

- Sorter Machine

- Tea Color Sorter

- Dal Mill Machine

- Sorting Machine

- Magaj Color Sorter

- Commandor Color Sorter Machine

- Service Center

- Contact Us

Rice Blending Machine

400000 INR/Unit

Product Details:

- Weight Approx. 420 kg

- Dimension (L*W*H) 2000 x 800 x 1650 mm

- Application Blending and Mixing Various Types of Rice

- Accuracy 1%

- Channels Single

- Capacity 500 - 1000 kg/hr

- Usage Commercial

- Click to View more

X

Rice Blending Machine Price And Quantity

- 400000 INR/Unit

- 1 Unit

Rice Blending Machine Product Specifications

- Single

- Rice Blending Machine

- Continuous

- 2 Horsepower (HP)

- Approx. 420 kg

- 500 - 1000 kg/hr

- 1%

- 2000 x 800 x 1650 mm

- Blending and Mixing Various Types of Rice

- Commercial

Rice Blending Machine Trade Information

- 5 Unit Per Month

- 1 Months

Product Description

Rice Blending Machine is a fully automated industrial unit that is commonly used in food industries to transform rice grains into powdered forms. It is installed with rice bins with respective capacities of 125 and 300 kilograms. The feeder system of this unit is equipped with best in class geared motor to ensure efficient material transfer. It is simple to use human machine interface makes it easier for a single user to operate this machine. The offered Rice Blending Machine can be delivered to our customers as per their demands with a supply ability of 5 units per month.

Specifications:

- Model: PEC/RB52

- Type: Volumetric Blender

- Components:

- Rice Bin- 1 Capacity: 125Kg

- With Proximity Sensor: M30

- With Screw Feeder with 0.25 hp geared motor

- With Manual Slide

- Rice Bin- 2 Capacity: 300Kg

- With Proximity Sensor: M30

- With Screw Feeder with 0.5 hp geared motor

- With Manual Slide

- Rotating Drum Type Rice Blending Machine with cup lifts.

- Drive: 1hp Geared Motor

- Electrical Panel:

- PLC to manage the blending capacity of rice being fed into the machine.

- Predefined blending ratio: 99:1

- VFD - 03nos for management of blending drums and screw feeders

- HMI- to manage the machine

Product details

| Power | 2 Kwh |

| Material of Construction | MS |

| Motor Power | 2 HP |

| Electricity Connection | Single Phase |

| Operation Mode | Automatic |

| Country of Origin | Made in India |

| Part Type | RICE MIXING MACHINE - BLENDER |

| Brand | MARK |

| Machines Required | Husker |

Efficient and Accurate Rice Blending

Engineered to deliver a continuous and precise blend, this Rice Blending Machine is ideal for commercial environments. Its 1% accuracy ensures consistent product quality, while the 2 HP electric motor provides reliable performance. The mild steel structure, enhanced by a powder-coated finish, guarantees long-term durability and resistance to wear, meeting rigorous usage demands.

User-Friendly Operation with Panel Controls

Designed with an intuitive control panel, the machine offers straightforward operation even for semi-skilled personnel. The system supports a hopper with a 150 kg capacity, ensuring smooth feeding and uninterrupted blending. Thanks to its semi-automatic design, monitoring and adjustments are simple, maximizing both safety and productivity.

FAQ's of Rice Blending Machine:

Q: How does the Rice Blending Machine operate for commercial-scale applications?

A: The machine uses a panel-based control system to facilitate easy operation. Users load various types of rice into the 150 kg capacity hopper, and the electric motor drives the blending mechanism. The process produces a continuous and homogenous mix, handling capacities of 500 to 1000 kg per hour with high accuracy.Q: What types of rice can be blended using this machine?

A: The Rice Blending Machine is suitable for mixing and blending a variety of rice types, including long-grain, short-grain, basmati, and specialty rice blends, making it versatile for exporters, manufacturers, and suppliers.Q: When is this machine most beneficial to use?

A: This machine is especially valuable when high-volume, consistent blending is needed-such as in rice mills, export houses, large kitchens, or food processing units requiring reliable and homogeneous rice mixtures.Q: Where can this Rice Blending Machine be installed?

A: The Rice Blending Machine's compact design and standard voltage requirements make it suitable for installation in commercial processing facilities, manufacturing plants, export units, and supplier warehouses throughout India and beyond.Q: What is the blending process and how is accuracy maintained?

A: The process begins by loading rice into the hopper, which feeds the rice to the blender via a channel. Internal mechanisms mix the rice thoroughly, while the panel-based control system ensures precise operation, delivering an accuracy of 1% in the final blend.Q: How is the machine used and maintained for optimal performance?

A: Regularly inspect and clean the hopper, blending chamber, and control panel to prevent residue build-up. Operate the machine within the recommended voltage range, and follow the manufacturer's maintenance schedule to ensure longevity and dependable performance.Q: What are the main benefits of using this Rice Blending Machine?

A: Key benefits include high capacity output, accurate and reproducible blending, durable mild steel construction, simple panel controls, and suitability for a wide range of commercial rice processing applications. Exporters and manufacturers benefit from improved efficiency and product uniformity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email